Power batteries are used in new energy vehicles, electric vehicles, photovoltaic, energy storage, wind power, 5G data centers, 3C electronics, intelligent terminals and other fields, the demand from the market for the battery industry provides a broad space for development. And "carbon neutral" "carbon peak" under the emerging track, the trillion-dollar market is opening.

Market size of $30 billion by 2025

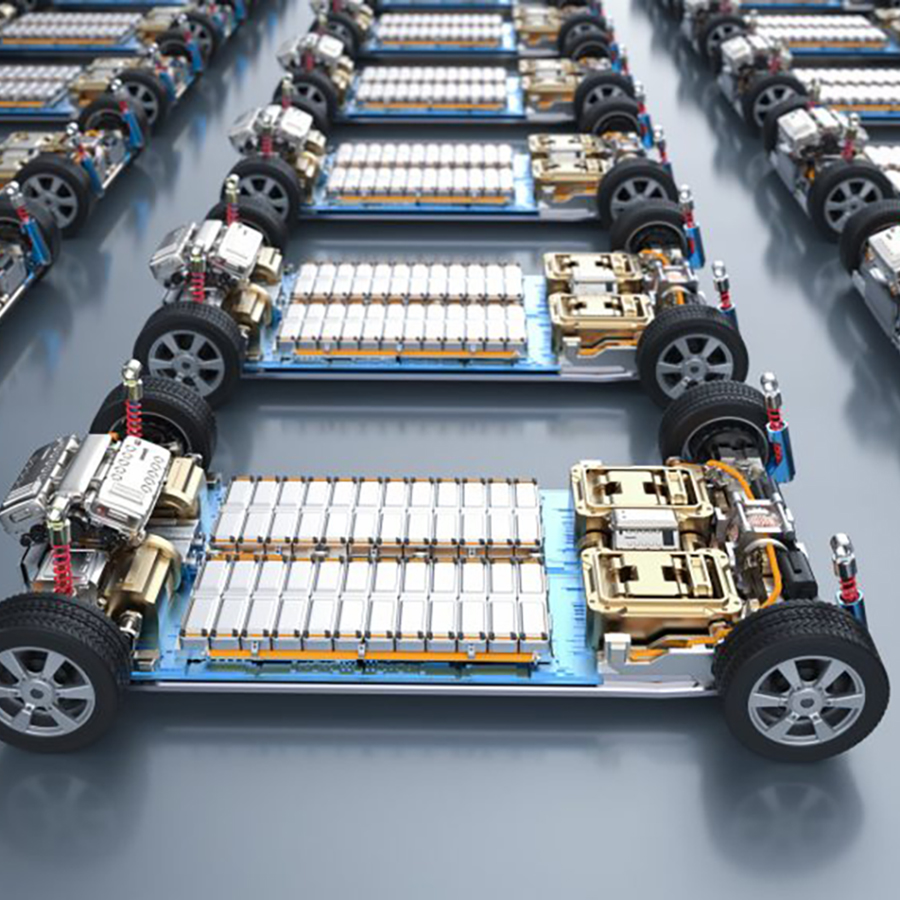

Lithium battery precision structural parts mainly include the top cover of the core shell, steel/aluminum shell, positive and negative soft connection, battery soft connection row. Lithium battery precision structural components have a direct impact on the safety, airtightness and energy efficiency of lithium batteries.

Previously, consumer electronics manufacturers on the application of consumer battery lithium battery battery structure will not be particularly high requirements, but vehicle manufacturers, power battery factory for the application of battery structure on the power battery requirements are very high. Because the battery structure not only affects the efficiency of the battery, but also affects the safety of the battery (the safety of the battery is too important to the battery factory and the OEM).

OEMs / power battery manufacturers on the requirements of the battery structure is mainly reflected in the battery structure of the technical indicators (technical indicators are directly related to the battery performance, safety and reliability), consistency (usually a car is integrated into the number of hundreds of battery cells, the differences in the battery cells will lead to the "short-plate effect", which seriously affects the overall performance of the module and pack), and other requirements. The requirements of lithium batteries are also very important. As a key component of lithium batteries, the cost of structural components accounts for about 6~7% of the total cost of the battery, which is comparable to the negative electrode, diaphragm and electrolyte. It is understood that precision structural components play a role in transmitting energy, carrying electrolyte, protecting safety, fixing and supporting the battery, and decorating the appearance, etc. These components are required to have specific functions, such as connectability, vibration resistance, heat dissipation, corrosion resistance, anti-interference, anti-static, etc., according to the different application environments. Starting Point Research Institute (SPIR) data show that by 2025 China's lithium battery shipments will reach 600GWh, the current unit value of battery structural components is about 0.5 billion yuan / GWh. Calculated on this basis, it is expected that by 2025, China's battery structural components market size is expected to reach 30 billion yuan, of which the power battery structural components to occupy a major share of the market is expected to be about 22 billion yuan.

GF Securities expects the global lithium battery structural parts industry scale to reach about 46 billion yuan in 2025. According to structural parts industry data, the price of lithium battery structural parts in 2020 is about 40 yuan / KWh. Assuming that the unit price of lithium batteries decreased by 5% annually, based on the global installed capacity of power batteries and forecasts for energy storage and consumption, it is expected to be close to 46 billion yuan in 2025, with a five-year compound growth rate of 34.74%.

Lithium battery precision structural parts mainly include the top cover of the core shell, steel/aluminum shell, positive and negative soft connection, battery soft connection row. Lithium battery precision structural parts have a direct impact on the safety, airtightness and energy efficiency of lithium batteries. According to statistics, the supply of raw materials for power battery precision structural parts has been stable in recent years. Its main raw materials include aluminum, copper, etc., accounting for about 53% of the total cost, raw material procurement prices and their trends, and the market price of the same or similar raw materials and their trends are relatively close. It should be noted that the power battery precision structure building industry has high industry barriers, high entry threshold, and very low substitutability.

The main reason is that the production of power battery structural products generally require precision production equipment and high level of production environment to ensure that, at the same time, the need to use flexible manufacturing equipment, CNC machine tools, industrial robots and other automation, high degree of refinement of high-end manufacturing equipment, and the manufacturing environment on the temperature, the dust content of the air, the degree of insulation of the equipment surface, etc., all have high requirements.

Last Article:The main opportunities for the development of lithium battery precision structural components industry

Next Article:Dongguan Seanda confirmed to attend the 4th Lithium "ABEC" Forum